- Direct Drive Mills

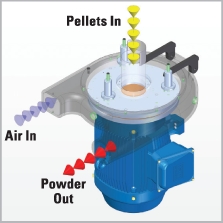

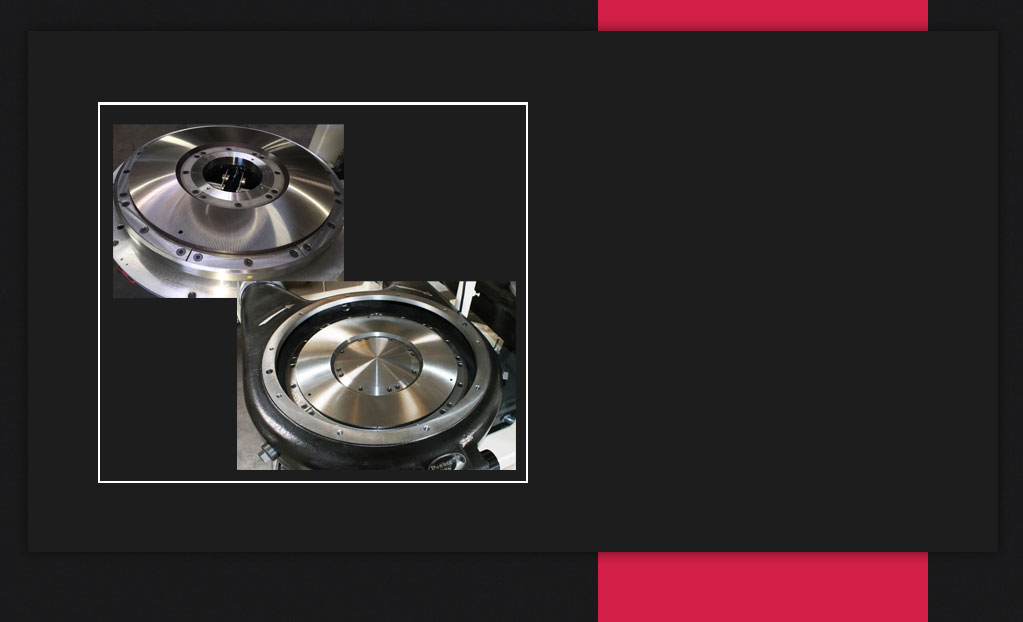

- This revolutionary design eliminates the use of industry standard belt drive. The flywheel for the rotating disks is directly connected to the motor shaft, eliminating the belt drive, bearing housing and motor adjustment fixture. The direct drive provides 100% of the available horse power, which belt drive models do not. The direct drive saves our customers the expense of stocking expensive drive parts, bearings, seals, belts, spindle shaft or complete bearing housing assembly. The direct drive also eliminates down time due to bearing or belt failure.

- Heavy Gauge Quick Disconnect Piping.

- More durable piping, less likely to be damaged during frequent clean downs.

- All Eaton Cutler Hammer Electrical Components

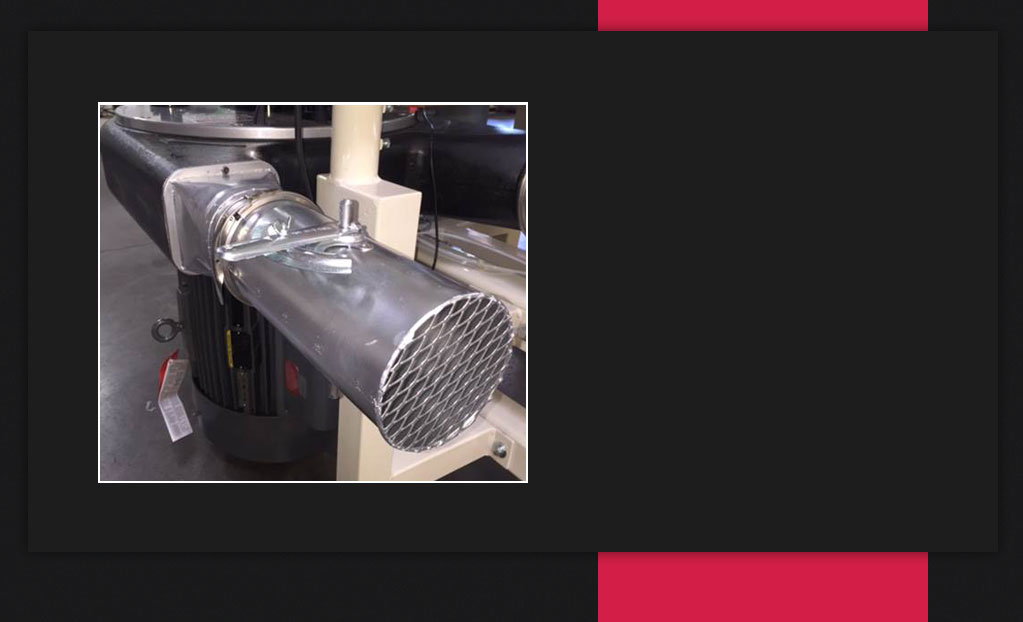

- 75 HP High-Efficiency Cast Iron Motors

- Large Capacity Rotationally Molded Plastic Pellet Hopper with Center Flow.

- 10 Cu. Ft. 350 lbs. capacity Center flow eliminates hang-ups of material in the hoppers.

- Extra thick, heavy-duty malleable steel housings are cast in one-piece for increased safety.

- 8″ HMI Operator Touch Screen with crystal clear display from any angle and designed for easy operation with many built-in features.

- Optional Variable Frequency Drives that reduce the in-rush of electricity to 30 AMPS and consumption during start-up. This reduces demand of electricity at start-up which results in huge electrical savings for our customers. 50 Hz machine are standard with VFD.

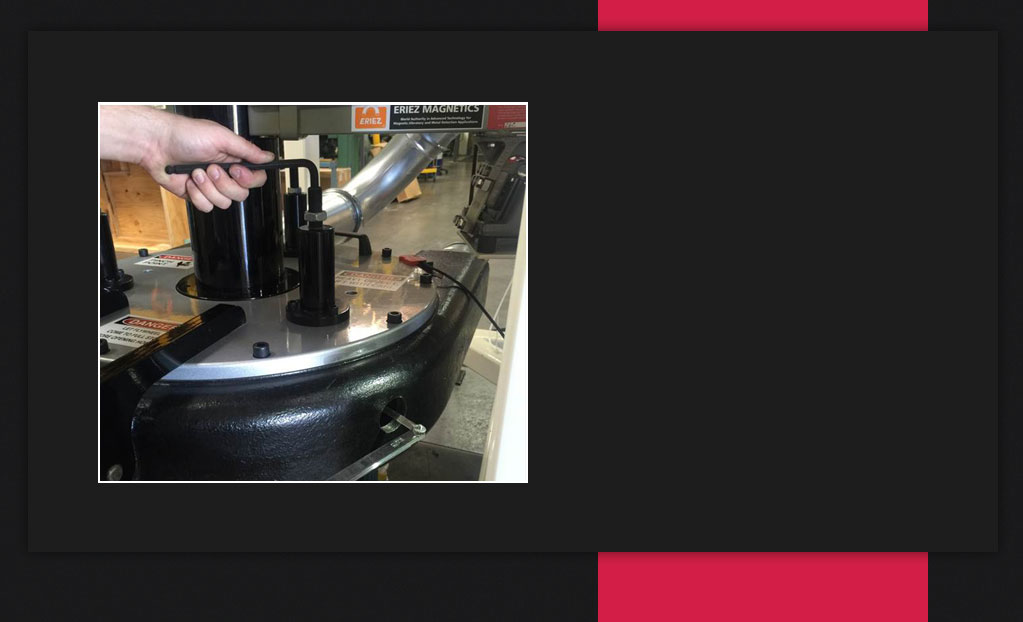

- High Output Vibratory Feeder- Eriez 26C- 99% efficient – professionally designed cyclone eliminates carryover dust and product loss.

- 10hp High-Efficiency Blower that creates the exact vacuum to move the product through the 8” Airlock system at the required velocity.

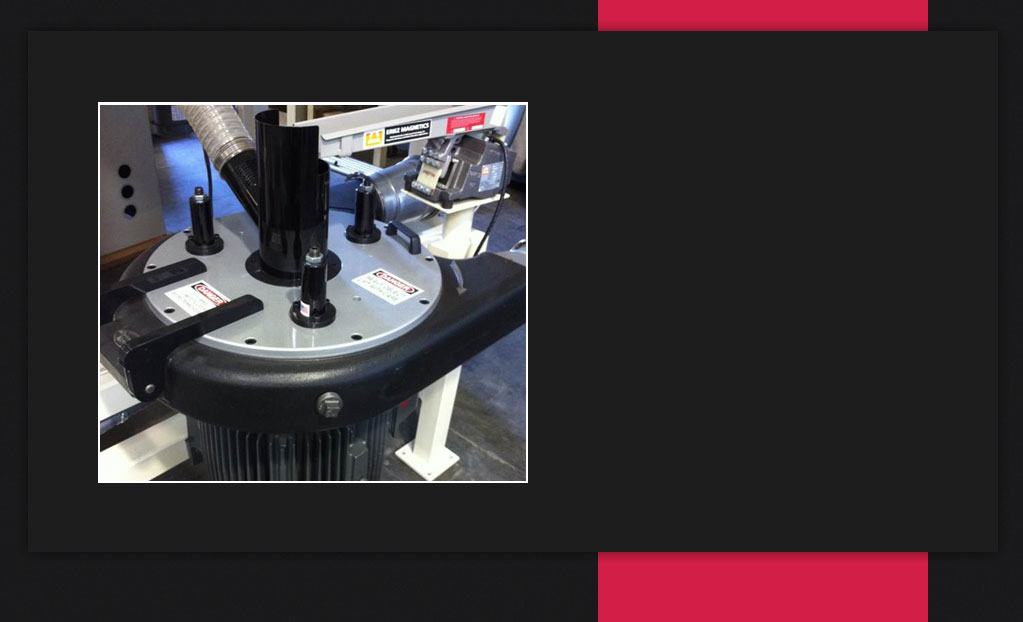

- (3) Single Stud Disk Gap Adjusters Per Mill.

- Allow adjustment of the disk gap from outside the mill. Integrated spring loaded mechanism on stud provides single point adjustment.

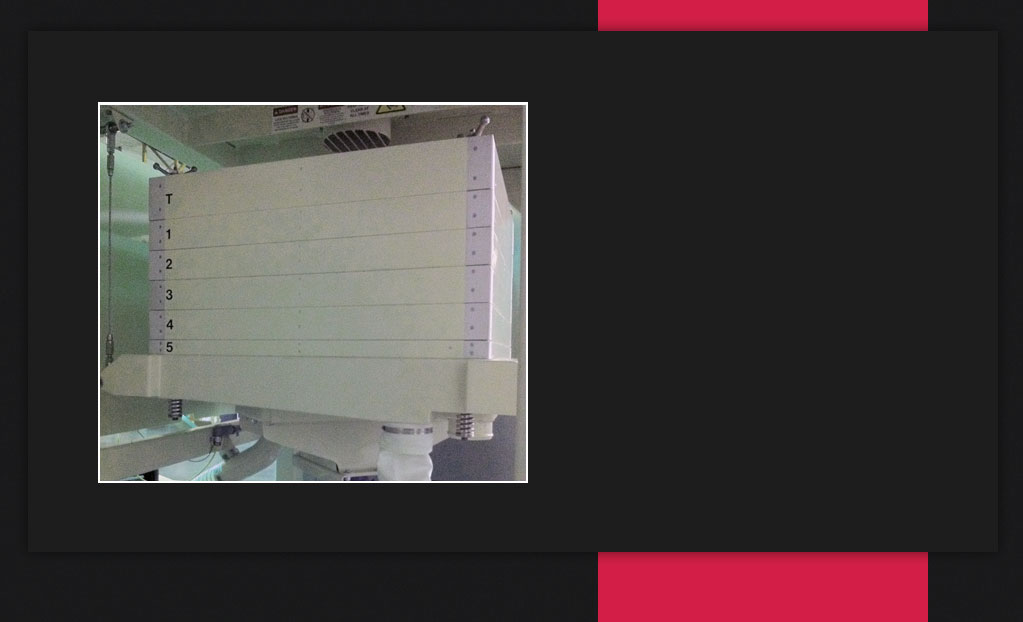

- 5-Deck Great Western Sifter.

Cost Savings Associated with In-house Pulverizing.

Pulverizing in-house generates savings as much as 6 to 8 cents per pound compared to purchasing your resin in powder form. Buying pellets and pulverizing in-house is an excellent alternative to make your company more competitive in today’s marketplace.

Our Commitment to Your Quality

Powder King® is unique in that our commitment to quality extends beyond what we manufacture into what you manufacture. Our disks and airflow management technology are engineered to consistently achieve perfect particle distribution and the required bulk density and dry powder flow. We have an operator-training program that provides operators a comprehensive understanding of pulverizing and focuses on maintaining the highest level of powder quality.

Greater Output than Comparable Models

Greater Output than Comparable Models Reduced Clean Down-time

Reduced Clean Down-time EC200 Embedded Controller

EC200 Embedded Controller 10″ HMI Touch Screen

10″ HMI Touch Screen Direct drive design with 75 Hp Premium Efficiency Cast Iron mill motor

Direct drive design with 75 Hp Premium Efficiency Cast Iron mill motor 5–Deck High Volume Sifter

5–Deck High Volume Sifter 20” Abrasive Resistant Disks

20” Abrasive Resistant Disks Single Tool Gap Adjusters

Single Tool Gap Adjusters Through-Put Rates 800-1100 lbs/hr

Through-Put Rates 800-1100 lbs/hr