Trade Shows and Events

Upcoming Meetings

2020 Executive Forum with IT-RO

March 30 – April 3

Lake Garda, Italy

2020 Annual Meeting & Rotoplas

September 21-24

Rosemont, IL

Upcoming Meetings

2020 Executive Forum with IT-RO

March 30 – April 3

Lake Garda, Italy

2020 Annual Meeting & Rotoplas

September 21-24

Rosemont, IL

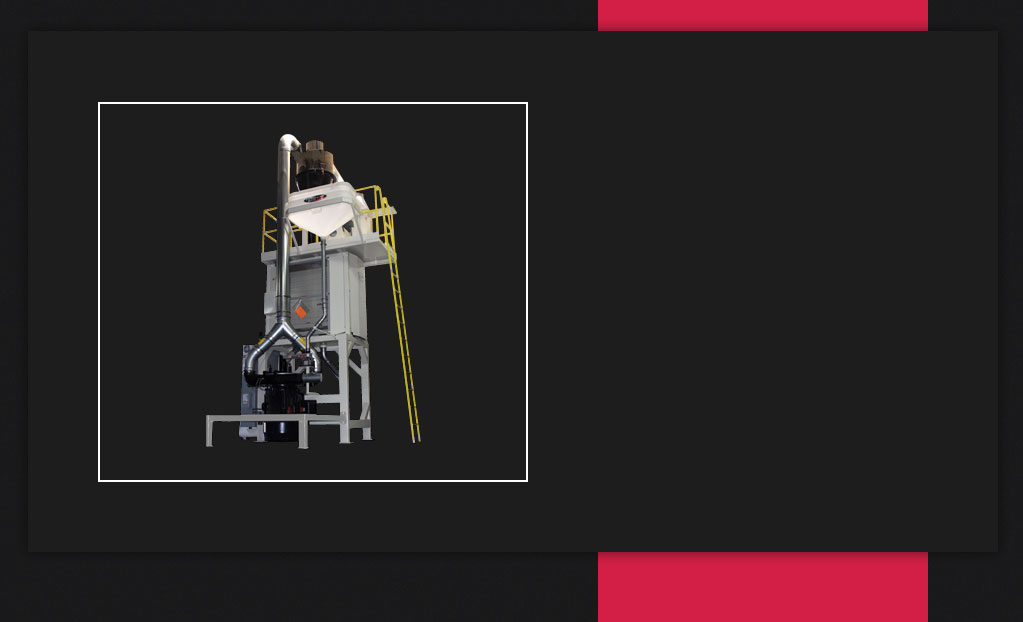

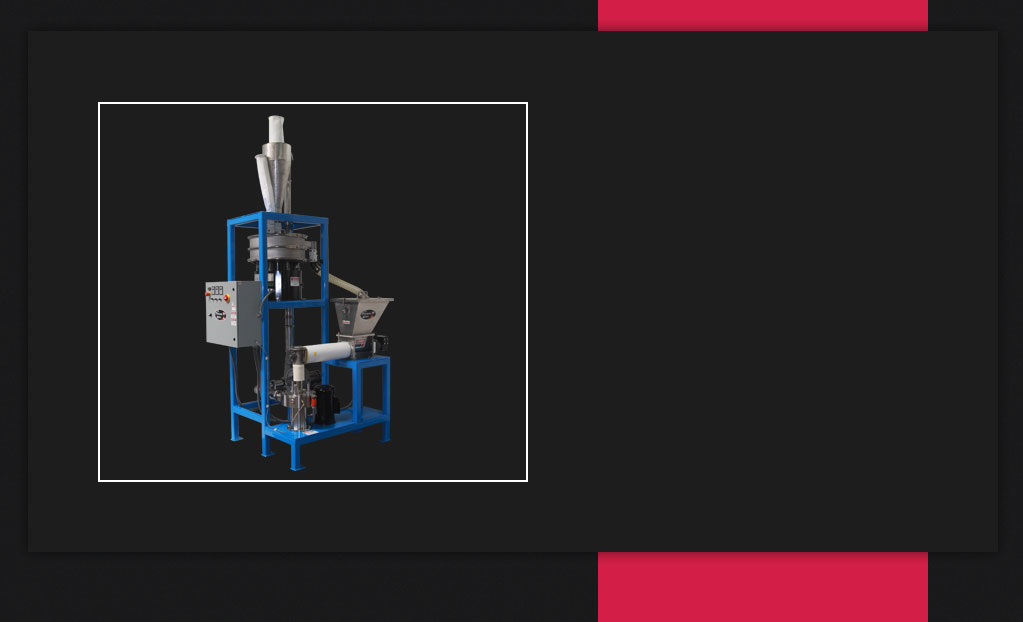

• New Patent Pending Mill Housing with Dual Air Inlet and Dual Material Outlets

• 8" HMI Touchscreen

• Eaton Logic PLC Operating System

• Direct Drive design with 150 Hp Premium Efficiency Cast Iron Mill Motor

• 9-Deck High Volume Sifter

• 20" Abrasion Resistant Disks

• Single Tool Gap Adjusters

• Through-Put Rates 1600-2200lbs/hr

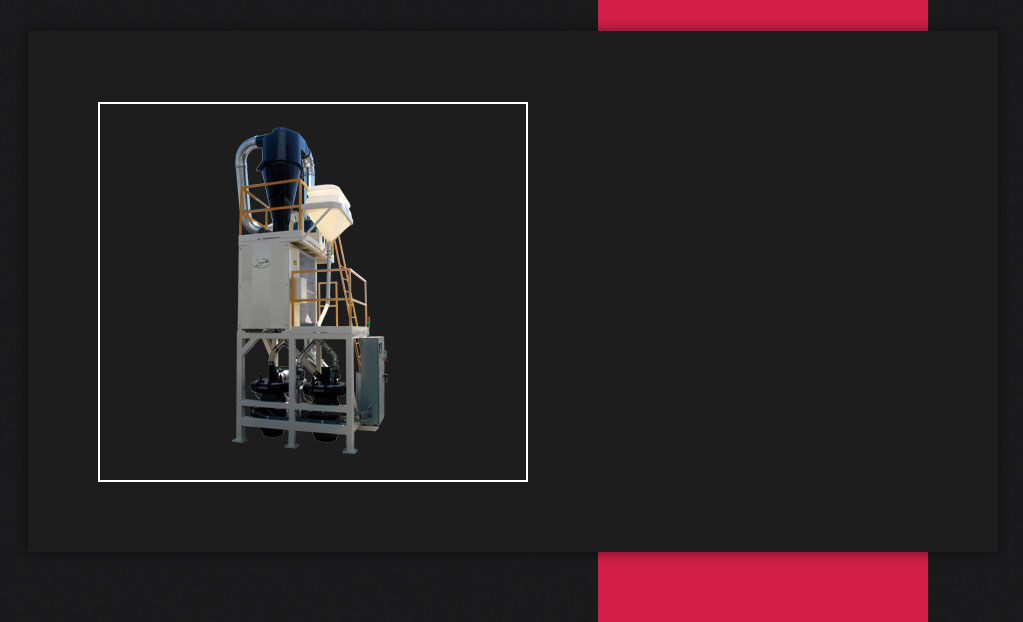

• 8" HMI Touchscreen

• Eaton Logic PLC Operating System

• Direct drive design with (2) 100 Hp Premium Efficiency Cast Iron mill motors

• 9–Deck High Volume Sifter

• Aerodynamic Mill Design for Increased Airflow and Cooling

• 20” Abrasive Resistant Disks

• Single Tool Gap Adjusters

• Through-Put Rates 1700-2200lbs/hr

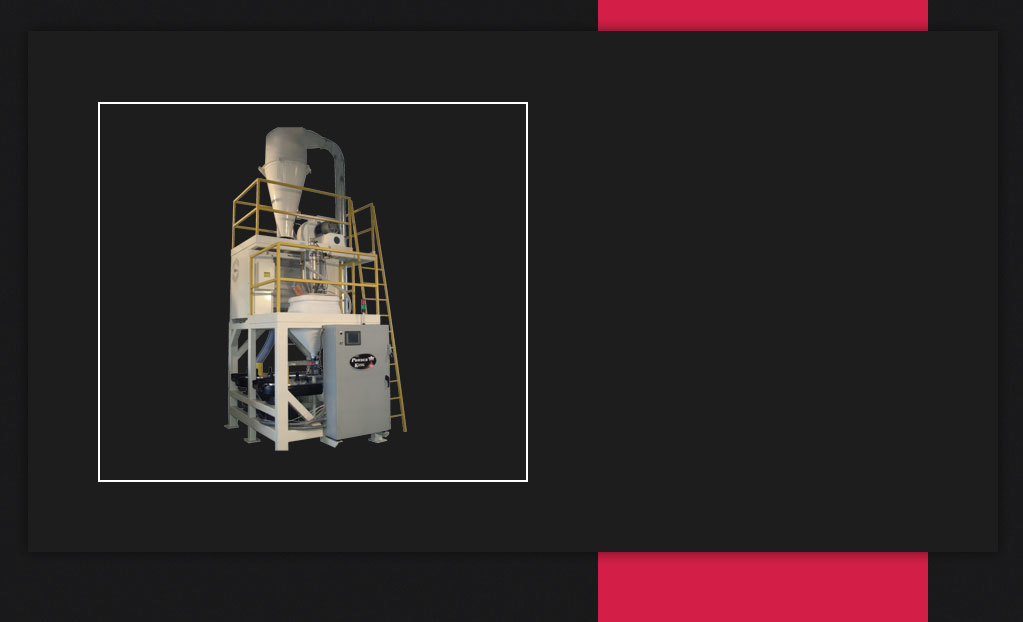

• 8" HMI Touchscreen Control

• Eaton Logic PLC Operating System

• Direct drive design with 75/60 Hp Premium Efficiency Cast Iron mill motor

• 6–Deck High Volume Sifter

• 20” Abrasive Resistant Disks

• Single Tool Gap Adjusters

• Through-Put Rates 1200-1600lbs/hr

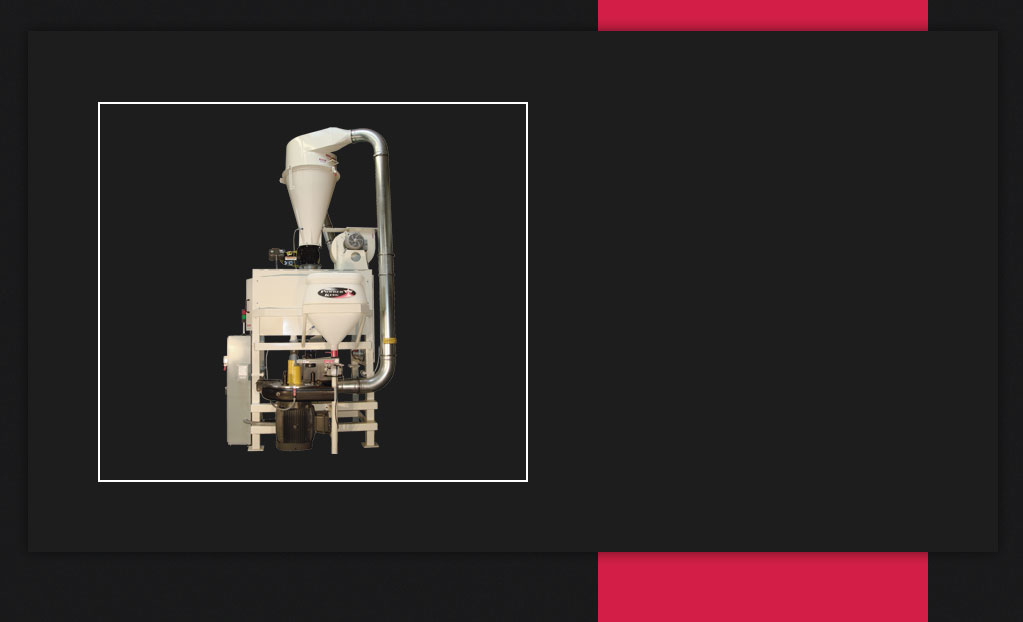

• 8" HMI Touchscreen

• Eaton Logic PLC Operating System

• Direct drive design with 75 Hp Premium Efficiency Cast Iron mill motor

• 5–Deck High Volume Sifter

• 20” Abrasive Resistant Disks

• Single Tool Gap Adjusters

• Through-Put Rates 800-1100 lbs/hr

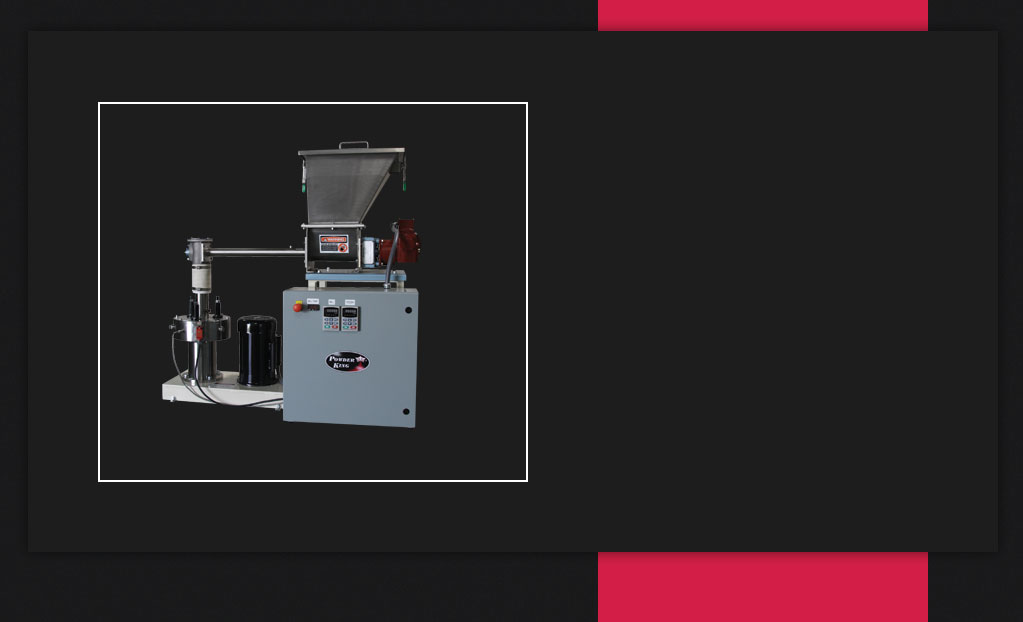

• Control Panel with Variable Speed Drives for Mill, Auger Feeder & Blower

• 24” Midwest Single-Deck Sifter for Precise Particle Separation

• Stainless Steel mill housing with integrated bearing housing

• 8” Abrasive Resistant Disks

• Flywheel Mounted with Machine Impeller on Tapered Shaft to Run Within .001”

• 5-HP Motor

• Single Tool Gap Adjusters

• Through-Put Rates 50 lbs/hr

• Control Panel with Variable Speed Drives for Mill & Auger Feeder

• Inverter Drives for the Mill Motor to Optimize Disk Speed

• Mill Housing with integrated bearing housing

• 8” Abrasive Resistant Disks

• Flywheel Mounted with Machine Impeller on Tapered Shaft to Run Within .001”

• 5-HP Motor

• Single Tool Gap Adjusters

• Through-put Rates 50 lbs/hr

• 8” Abrasive Resistant Disks

• Aluminum mill housing with integrated bearing housing

• Flywheel Mounted with Machine Impeller on Tapered Shaft to Run Within .001”

• 5-HP Motor

• Single Tool Gap Adjusters

• Through-Put Rates 50 lbs/hr

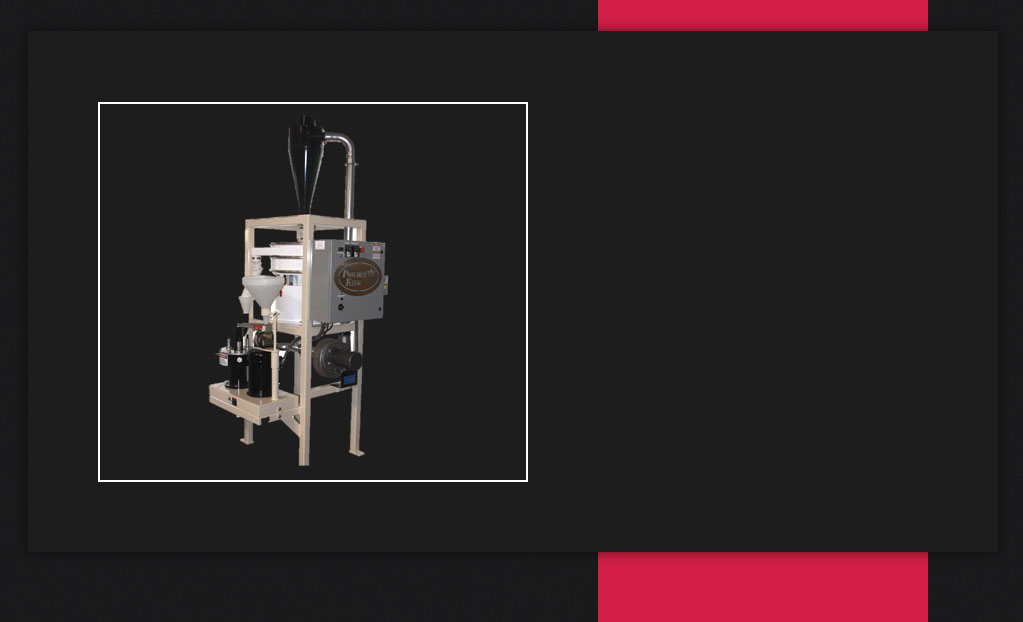

• Control Panel with Temperature Controller

• Inverter Drives for the Mill & Blower Motor to Optimize Disk Speed

• 8” Abrasive Resistant Disks

• Sifter for Precise Particle Separation

• Aluminum Mill Housing with Integrated Bearing Housing

• Flywheel Mounted with Machine Impeller on Tapered Shaft to Run Within .001”

• 5-HP Motor

• ¾ HP Built-in Blower Fan & Cyclone

• Single Tool Gap Adjusters

• Through-Put Rates 50 lbs/hr

Powder King® mills have time and time again proven to give our customers the performance they demand from a pulverizing system. When it comes to performance Powder King® is on your side to deliver.

Powder King® is known for their reliability to deliver the highest quality pulverizing system available in the industry. We understand that our customers need a system that can withstand punishing conditions in the harshest environments, whether your production requirements are from Polyethylenes for rotational molding and colored compounds or recycling of PVC, PE or other abrasive plastics. The Powder King® pulverizing system will deliver reliability that our customers expect.

Powder King® knows that efficiency is also a key aspect to any equipment. With this at the forefront of every pulverizing system designed, Powder King® uses only the most premium efficient motors for our mills and other component motors. We also use highest quality tool steels for the pulverizers disks and mill components. The PLC control panel electronics are also high quality name brand for years of trouble free operation. All other structural manufacturing and designed components meet the strictest guidelines for our systems functionality. When it comes to efficiency, you have Powder King® as your partner in making your profit grow.